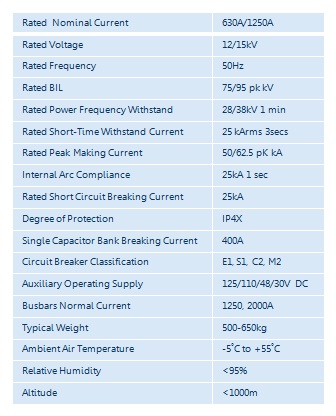

ECLIPSE (630A) & (1250A)

12kV Fixed Pattern Indoor Metal Enclosed Vacuum Switchgear

The Eclipse is designed to provide a lifetime unrivalled service, bringing together one of the most advanced operating mechanisms available on the market today – the award winning magnetic actuator technology – with vacuum interruption and the simplicity of air insulation in a compact, fixed pattern design. Appreciated throughout the distribution network and across every business sector, the Eclipse currently holds a dominant market position for 11kV indoor switchgear.

The Eclipse is also now available as a pre-engineered solution in ratings up to 25kA, 2000A. Alternatively, it can be fully engineered to meet exact customers needs.

Rating/Specifications

KEY FEATURES

Superior, proven Fit & Forget technology with minimal maintenance.

Superior, proven Fit & Forget technology with minimal maintenance. The fixed pattern design has the simplicity of air insulation and, with the low parts count (the total parts count has been reduced by a factor of x20 and the number of moving parts by a factor of x50), is more compact (500mm wide) than equivalent rated GIS equipment.

The fixed pattern design has the simplicity of air insulation and, with the low parts count (the total parts count has been reduced by a factor of x20 and the number of moving parts by a factor of x50), is more compact (500mm wide) than equivalent rated GIS equipment. The Eclipse boasts of superior operator safety with a fully interlocked disconnector selector mechanism, animated front panel mimic and a front access cable test facility, eliminating the need for any intrusive access to high-voltage compartments

The Eclipse boasts of superior operator safety with a fully interlocked disconnector selector mechanism, animated front panel mimic and a front access cable test facility, eliminating the need for any intrusive access to high-voltage compartments

Endurance tested to 10,000 operations

Endurance tested to 10,000 operations Environmentally friendly vacuum interrupters

Environmentally friendly vacuum interrupters Internal arc containment

Internal arc containment Voltage Presence Indication System (VPIS) is fitted as standard to all panels (circuit)

Voltage Presence Indication System (VPIS) is fitted as standard to all panels (circuit) Reliable control – supplied with an integral control module, providing indication, trip circuit supervision and self-diagnostics

Reliable control – supplied with an integral control module, providing indication, trip circuit supervision and self-diagnostics Customer’s choice of protection

Customer’s choice of protection

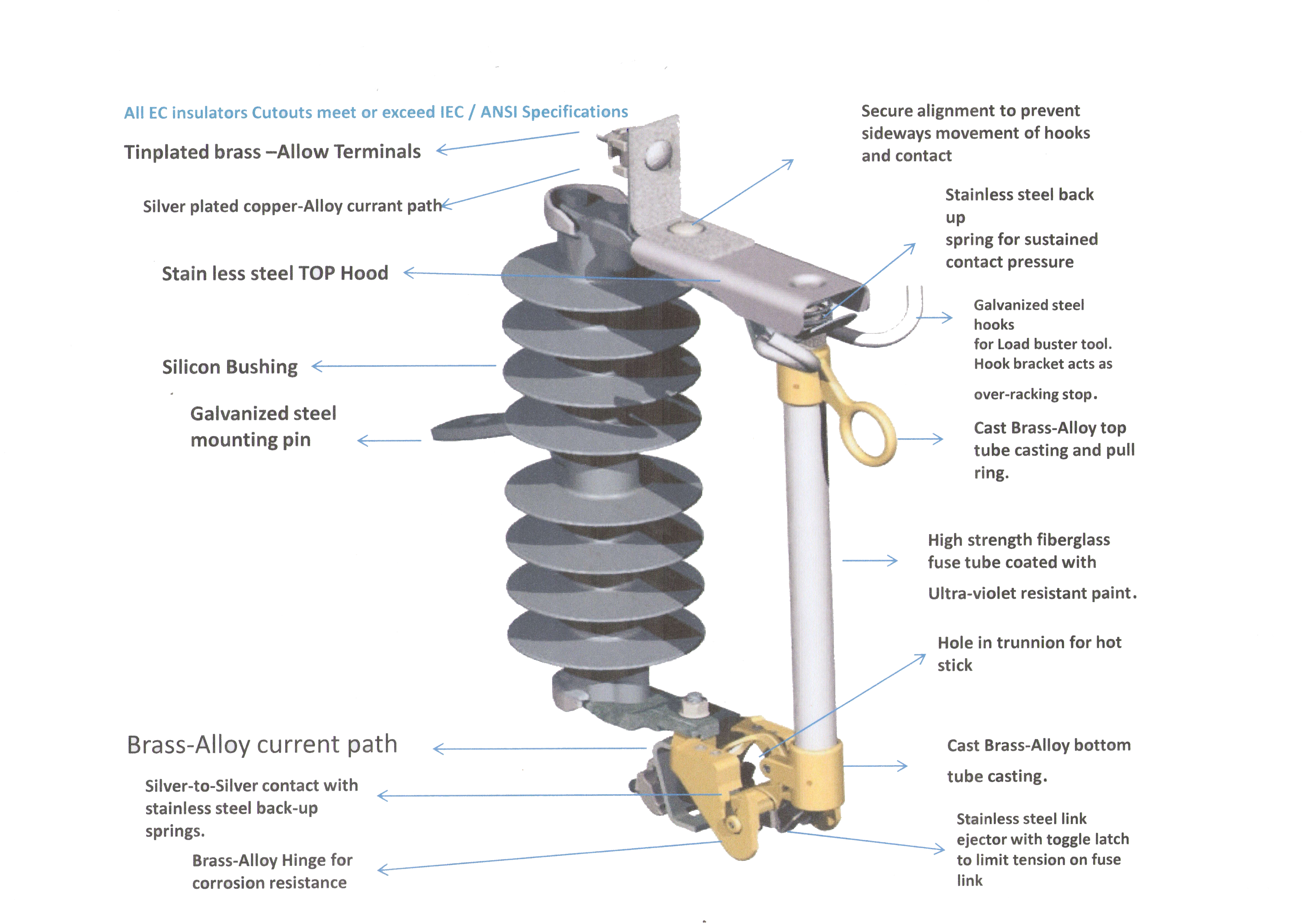

Fuse CutOut

Drop out fuse cutouts and load switchingfuse cutouts areforoutdoorusedhighvoltagedevice.To be connectedwith incoming feederof distributing transformerof distributionlinesit mainlyprotect transformeror linesfromshortcircuitandoverload, and on/offloadingcurrent.

Dropout fuse cutout is composedof insulatorsupports andfuse tube, staticcontactsis fixedon twosides of-insulatorsupportand moving contactis installedon twoendsof fusetube. Fuse tubeis composedof inside arc-extinguishing tube, outerphenoliccompoundpapertubeor epoxy glass tube.

Load Switch fusecutoutprovidesenforced elasticauxiliarycontactsand arc-extinguishing enclosurefor switchingon/off loading current.

At normally working via fuse link tightenedthe fuseis fixedtoformupa close position.In case system currentfaults,faultscurrentresultin fuse melt immediatelyandtakeplace electricarc,which let arc- extinguishingtube being heated and explodea lot of gas. Thiswillprovidehighpressureand blowoff the arcalong the tube. After fuse link melt, movingcontacthas no lightenedstrength again, mechanismis lockedandfuse tubedropout.Cutoutnow is inopen position. Whenit needs toswitch off during cutout loading,operatorshallvia insulating operating bar pullthemoving contact,atits beginningmaincontact andauxiliary staticcontactis contactedstill.Whiling,pulling the auxiliarycontactis separatedbetween auxiliarycontactsthereoccurelectricarc and thearc willbe lengthenedin arc-extinguishing enclosuregap andmeanwhilearc-extinguishing explodegas toblow off the arc duringcurrentpassingzero